Project Borrega is a brand new fully custom-made jeans project that will launch this spring in Fukuyama City, Hiroshima Prefecture, a denim production area that is trusted and respected by top designers both in Japan and abroad, and where world-class denim production experts have gathered.

'Not just any custom-made jeans!'

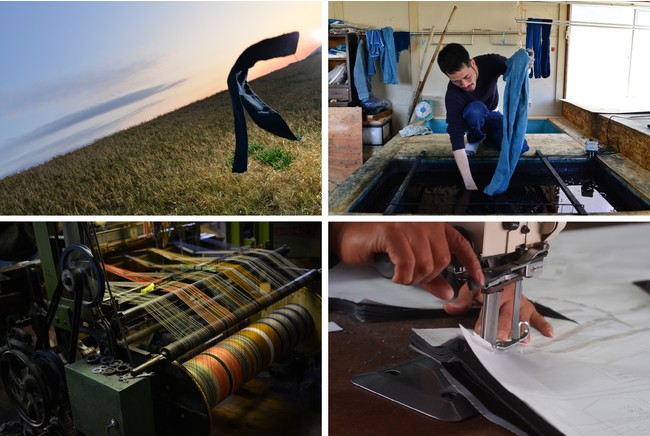

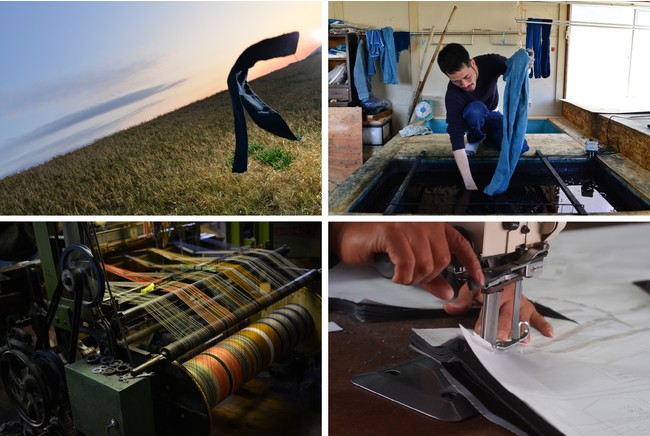

The first thing that will surprise you is the price: 1 million yen. The production of our fully custom-made jeans begins with the customer selecting the raw materials. Every material and process, from dyeing, fabric, patterning, cutting, and sewing to auxiliary materials like buttons and rivets, has a special story embedded in it until each pair of jeans is completed. You'll encounter many first-time experiences along the way. When you've finished making it, will you really think that this price is too high?

Making denim production visible

One of the features of this project is the close relationship between customers and the producers and artisans. The denim production process is open to the public, and private factory tours allow you to see up close everything from the indigo farming site to the artisans' dyeing and sewing at the factory. There are also programs that allow customers to participate in the production themselves. We offer an entirely new fusion of industry and tourism: Manufacture Tourism. All products come with a lifetime warranty and can be maintained and re-dyed. This is sure to become a piece of clothing that will last a lifetime.

'Respect for Traditional Industries'By eliminating preconceived notions about denim materials and component selection, customers can choose precious materials that have never been used in denim before. They can also use "Sanada Himo" (Sanada cords), a craft that has been passed down in Fukuyama for nearly 100 years and is still practiced by only a few artisans in Japan, and the venerable "Kinran" (gold brocade). We also recommend "fully natural indigo dyeing" using Japanese knotweed, one of only a few producers in Japan that can perform the entire process from cultivation to dyeing. The project's motto is to prioritize the procurement of local materials and techniques. Another unique aspect of this project is its collaboration with other industries not involved in the traditional denim production process.

Achieving SustainabilityAt the same time, we actively adopt cutting-edge materials and technologies that take into consideration SDGs, sustainability, and eco-friendliness. Our project stands out through collaborations with companies that offer technologies such as Tencel, which uses less water to grow raw materials, fabric made from recycled denim scraps, and eco-dyeing that meets the strict wastewater standards of the Seto Inland Sea.

The Project's Hidden Mission

The project team's primary goal is customer success, achieving customer satisfaction and meeting their specific needs. Another goal is contributing to the local community, society, and industry. The issue of succession is becoming a serious problem in regional production sites. By focusing on artisans, we hope to increase contract revenue, improve the image of the profession, and resolve issues of succession. We also value serving the local community and industry, such as providing surplus materials to local denim schools. Proceeds from this event will also be returned to the artisans.

We have many other surprises in store that only participants will know about. First, come and meet our denim artisans in Fukuyama.

[How to apply]

Applications will open on the website below from March 31, 2021. We will then share your experience with the world.

https://www.boleega.com/

[Price]

1,000,000 yen (excluding tax)

*For standard specifications. Prices will vary depending on the materials and parts selected.

[Contact Information]

Project Boleega

Representative: Tachibana Miki

703 Nakajima, Ekiya-cho, Fukuyama City, Hiroshima Prefecture

URL: https://www.boleega.com/

[Reference Materials]

"About the denim production process and the stories embedded in the materials and parts"

(1) Indigo dyeing

Young samurai Kenta Fujii, who studied under Arai Osamu, the sixth generation owner of Arai Seiaijo, a recipient of the Yellow Ribbon Medal and one of Japan's five surviving indigo artisans, handles an integrated production system from cultivation to product creation, which is rare even in Japan. He continues the traditional indigo dyeing method passed down in Japan since ancient times, known as "natural lye fermentation," which does not use any chemicals. Indigo dyeing does not pollute the environment, and by using fallow rice fields, it also contributes to regional revitalization. Indigo dyeing also has the hidden benefit of preventing insects.

(2) Dyeing

The fabric is dyed using Sakamoto Denim Co., Ltd.'s "Eco Dyeing System." By adopting the technology of the world's leading denim dyeing company, we are able to produce environmentally friendly products.

Reference website: https://sakamoto-d.co.jp/eco.html

(3) Fabric

You can choose from fabrics made by Shinohara Textile Co., Ltd., a manufacturer of highly specialized, high-quality fabrics, known in the textile industry as "Tencel Shinohara." Tencel fabric is made from wood chips, which, compared to cotton, requires significantly less water from cultivation to production, making it an environmentally friendly fabric. There are also many other variations, such as recycled PET bottle fabrics and fabric made from scraps recycled into denim, with over 1,000 different fabrics to choose from. Project Borrega offers a special plan that allows you to choose from high-quality cottons collected from around the world.

Reference website: https://www.shinotex.jp/initiatives/

(4) Sewing

Mill Create Ltd. is a sewing company specializing in "sample production," and is responsible for the extremely important process in the apparel industry of creating the first sample. At the same time, this means that the company employs some of the most highly skilled craftsmen.

Reference website: http://millcreate.com/

(5) Auxiliary materials

By collaborating with local ironworks, it is possible to custom-make the buttons, rivets and other auxiliary materials used in denim. Employing local companies supports local industry, and by creating unique products it stimulates the curiosity of craftsmen, leading to the development of new products and improved skills. This has the potential to raise the status of craftsmen and increase contract work, and completing the process within the region is also in line with eco-ism.

Reference sites: http://www.egi-ss.co.jp/, https://sangyoco.co.jp/business/

Click here for company press release details

'Not just any custom-made jeans!'

The first thing that will surprise you is the price: 1 million yen. The production of our fully custom-made jeans begins with the customer selecting the raw materials. Every material and process, from dyeing, fabric, patterning, cutting, and sewing to auxiliary materials like buttons and rivets, has a special story embedded in it until each pair of jeans is completed. You'll encounter many first-time experiences along the way. When you've finished making it, will you really think that this price is too high?

Making denim production visible

One of the features of this project is the close relationship between customers and the producers and artisans. The denim production process is open to the public, and private factory tours allow you to see up close everything from the indigo farming site to the artisans' dyeing and sewing at the factory. There are also programs that allow customers to participate in the production themselves. We offer an entirely new fusion of industry and tourism: Manufacture Tourism. All products come with a lifetime warranty and can be maintained and re-dyed. This is sure to become a piece of clothing that will last a lifetime.

'Respect for Traditional Industries'By eliminating preconceived notions about denim materials and component selection, customers can choose precious materials that have never been used in denim before. They can also use "Sanada Himo" (Sanada cords), a craft that has been passed down in Fukuyama for nearly 100 years and is still practiced by only a few artisans in Japan, and the venerable "Kinran" (gold brocade). We also recommend "fully natural indigo dyeing" using Japanese knotweed, one of only a few producers in Japan that can perform the entire process from cultivation to dyeing. The project's motto is to prioritize the procurement of local materials and techniques. Another unique aspect of this project is its collaboration with other industries not involved in the traditional denim production process.

Achieving SustainabilityAt the same time, we actively adopt cutting-edge materials and technologies that take into consideration SDGs, sustainability, and eco-friendliness. Our project stands out through collaborations with companies that offer technologies such as Tencel, which uses less water to grow raw materials, fabric made from recycled denim scraps, and eco-dyeing that meets the strict wastewater standards of the Seto Inland Sea.

The Project's Hidden Mission

The project team's primary goal is customer success, achieving customer satisfaction and meeting their specific needs. Another goal is contributing to the local community, society, and industry. The issue of succession is becoming a serious problem in regional production sites. By focusing on artisans, we hope to increase contract revenue, improve the image of the profession, and resolve issues of succession. We also value serving the local community and industry, such as providing surplus materials to local denim schools. Proceeds from this event will also be returned to the artisans.

We have many other surprises in store that only participants will know about. First, come and meet our denim artisans in Fukuyama.

[How to apply]

Applications will open on the website below from March 31, 2021. We will then share your experience with the world.

https://www.boleega.com/

[Price]

1,000,000 yen (excluding tax)

*For standard specifications. Prices will vary depending on the materials and parts selected.

[Contact Information]

Project Boleega

Representative: Tachibana Miki

703 Nakajima, Ekiya-cho, Fukuyama City, Hiroshima Prefecture

URL: https://www.boleega.com/

[Reference Materials]

"About the denim production process and the stories embedded in the materials and parts"

(1) Indigo dyeing

Young samurai Kenta Fujii, who studied under Arai Osamu, the sixth generation owner of Arai Seiaijo, a recipient of the Yellow Ribbon Medal and one of Japan's five surviving indigo artisans, handles an integrated production system from cultivation to product creation, which is rare even in Japan. He continues the traditional indigo dyeing method passed down in Japan since ancient times, known as "natural lye fermentation," which does not use any chemicals. Indigo dyeing does not pollute the environment, and by using fallow rice fields, it also contributes to regional revitalization. Indigo dyeing also has the hidden benefit of preventing insects.

(2) Dyeing

The fabric is dyed using Sakamoto Denim Co., Ltd.'s "Eco Dyeing System." By adopting the technology of the world's leading denim dyeing company, we are able to produce environmentally friendly products.

Reference website: https://sakamoto-d.co.jp/eco.html

(3) Fabric

You can choose from fabrics made by Shinohara Textile Co., Ltd., a manufacturer of highly specialized, high-quality fabrics, known in the textile industry as "Tencel Shinohara." Tencel fabric is made from wood chips, which, compared to cotton, requires significantly less water from cultivation to production, making it an environmentally friendly fabric. There are also many other variations, such as recycled PET bottle fabrics and fabric made from scraps recycled into denim, with over 1,000 different fabrics to choose from. Project Borrega offers a special plan that allows you to choose from high-quality cottons collected from around the world.

Reference website: https://www.shinotex.jp/initiatives/

(4) Sewing

Mill Create Ltd. is a sewing company specializing in "sample production," and is responsible for the extremely important process in the apparel industry of creating the first sample. At the same time, this means that the company employs some of the most highly skilled craftsmen.

Reference website: http://millcreate.com/

(5) Auxiliary materials

By collaborating with local ironworks, it is possible to custom-make the buttons, rivets and other auxiliary materials used in denim. Employing local companies supports local industry, and by creating unique products it stimulates the curiosity of craftsmen, leading to the development of new products and improved skills. This has the potential to raise the status of craftsmen and increase contract work, and completing the process within the region is also in line with eco-ism.

Reference sites: http://www.egi-ss.co.jp/, https://sangyoco.co.jp/business/

Click here for company press release details

The press releases featured in this article have been provided by PR TIMES Inc. and are reproduced verbatim. FASHION HEADLINE does not endorse the products or services featured, nor does it guarantee the content of the press releases. For inquiries regarding the content of this article, please contact PR TIMES Inc. (https://prtimes.jp/) directly.

![Our Fashion Story [vol.28_ DIOR × Contemporary]](https://wrqc9vvfhu8e.global.ssl.fastly.net/api/image/crop/533x712/images/upload/2025/11/1d7732ea5c65c54c096829dba8830b9e.jpg)

![Our Fashion Story [vol.28_ DIOR × Contemporary]](https://wrqc9vvfhu8e.global.ssl.fastly.net/api/image/width/273/images/upload/2025/11/1d7732ea5c65c54c096829dba8830b9e.jpg)